Fatigue Advisor, the Creo Simulate Extension to Evaluate Product Design for Durability

Download a 30-day Trial of Creo 7.0!

By form submission, you agree to the Terms of Service

ABOUT

Creo Fatigue Advisor:

Material Fatigue Analysis to Bolster Product Reliability

You know that even if stresses are well under safe values, materials subjected to repetitive or fluctuating stress can fracture, break in two, or simply snap without warning. The impact on your brand’s reputation, and on the safety of those using your product, could range from annoying to disastrous. You need to know how long you can expect the product to last.

Creo Fatigue Advisor Extension enables you to bolster product reliability by simulating and improving the fatigue performance of your design before you build a single prototype.The software also includes rainflow cycle counting and plastic strain extrapolation.

Using Creo Fatigue Advisor Extension you can improve product quality, reduce after-market service and warranty expenses, and avoid costly product recalls and their impact on your brand. Put Creo Fatigue Advisor to work for you.

-

USER INTERFACE

USER INTERFACE

PTC Creo Simulate and PTC Creo Fatigue Advisor Extension have the same user interface, workflow and productivity tools that are standard throughout the PTC Creo family. The combination of PTC Creo Simulate and PTC Creo Fatigue Advisor can be used as a standalone application or as an extension of PTC® Creo® Parametric™.

-

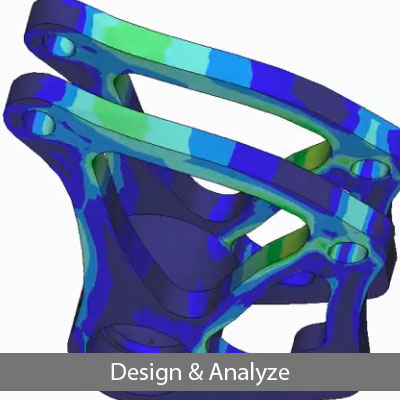

DESIGN FOR DURABILITY

DESIGN FOR DURABILITY

With 80% to 90% of all structural failures resulting from fatigue, think of the advantage you’d have if you could evaluate your designs for durability right from the outset of the design process. With Creo Fatigue Advisor, you can clearly understand the life of your product to avoid surprises, such as warranty costs and underperforming products, down the road.

-

WELL DOCUMENTED

Features

Creo Fatigue Advisor was Built with your Business in Mind

Images & Videos

Examples Using Creo Fatigue Advisor

Select Category

-

Mechanism Dynamics

Mechanism DynamicsDetermine reaction forces in mechanism design and define cam/follower connections between parts in the mechanism.

-

Tolerance Analysis

Tolerance AnalysisAutomatic validation of dimensions and dimension loops and graphical display of statistical distributions.

-

Mold Filling Analysis

Mold Filling AnalysisIdentify potential mold filling problems and improve design quality, reduce manufacturing cycle times and rework of molds.

-

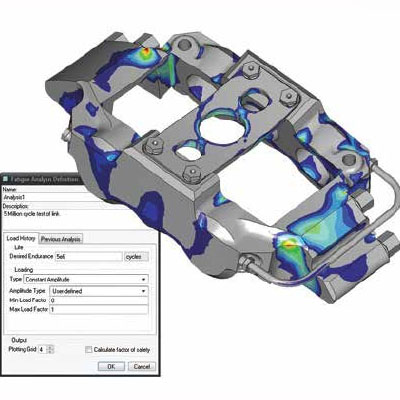

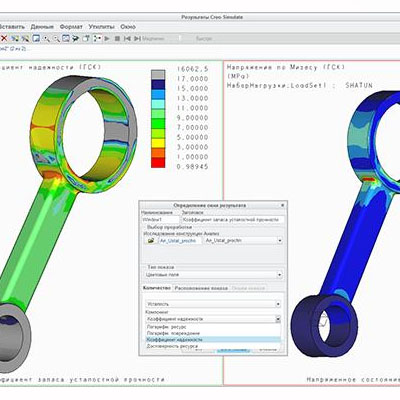

Fatigue Analysis

Fatigue AnalysisPredict the life of metal structures that are prone to fatigue failure and investigate the impact design changes have on endurance.

-

Human Factor Analysis

Human Factor AnalysisEnsure conformance with safety, health, ergonomics and workplace standards and guidelines.

-

-

-

-

-

See More Videos on Creo Fatigue Advisor